LafargeHolcim Makes A Case for Sustainable Construction

The Best Bet. Or is it?

The Best Bet. Or is it?

The Cement industry is the source of about 8% of all the world’s carbon dioxide (CO2) emissions, according to think tank Chatham House. If the cement industry were a country, it would be the third largest emitter in the world – behind China and the US. It contributes more CO2 than aviation fuel (2.5%) and is not far behind the global agriculture business (12%). But cement which is the single most man-made material used in the world seldom creates any waves in media. The reason, it has shaped much of our built environment, despite having a massive carbon footprint. To achieve Climate change goal, annual emissions from cement are required to fall by at least 16% by 2030.

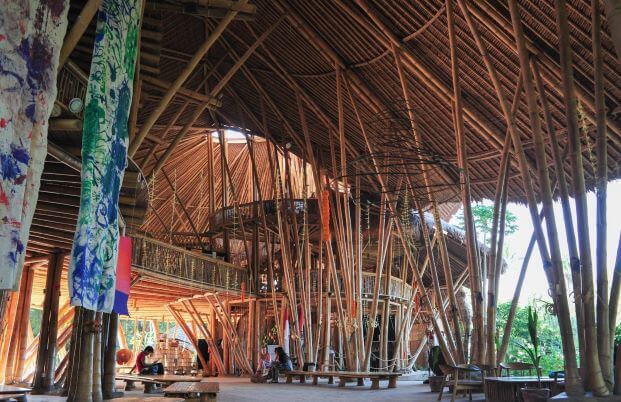

For Lafarge Holcim, the world’s largest cement manufacturer, out side of China with its dodgy numbers, there is this a more urgent need to find answers to the questions the industry faces. Thus, carious keynote addresses, workshops, and excursions of the forum focused on strategies to ‘re-materialise’ construction by reducing consumption throughout the material cycle, from extraction to processing, transport, installation, maintenance, and removal – contributing to a leaner industry.

The unrivaled attributes of concrete have helped boost global cement production since the 1950s, with Asia and China accounting for the bulk of growth from the 1990s onwards. From wooden sleepers on rail tracks to street furniture, besides of course large infrastructure projects, concrete truly came into its own from the time China embarked on its massive growth phase. Production has increased more than thirtyfold since 1950 and almost fourfold since 1990. China used more cement between 2011 and 2013 than the US did in the entire 20th Century. This is also one of the reasons why China’s emissions after a dip have skyrocketed. After coal, growth in electricity demand was driven by sectors linked to China’s construction industry – iron, steel and other metals; cement; glass and construction accounted for two-thirds of the growth in industrial power demand.

The 6th LafargeHolcim Forum investigated ‘changing paradigms’ (materials for a world not yet built), ‘shifting the flows, pulling the strings’(stock, flows, and their dynamics), ‘From manual to digital and vice versa’ (digitalization, labor, and construction), and ‘Catch 22’ (material needs vs material impact).

Michael Braungart (Germany), Cradle-to-Cradle Chair, Erasmus University Rotterdam, asserted the need to depart radically from the approach to design that had created the problem. “If you just perfect the wrong design, you end up with a design that is perfectly wrong,” he said.

Lord Norman Foster, Chairman and Founder of Foster + Partners (UK), showed the interconnection between design and materials selection using examples of his work, including the large-scale Apple Park corporate headquarters of Apple in California, and Bloomberg’s European headquarters in London. Foster also referred to small-scale work, including Mia Engiadina Mountain Hub in Switzerland that addresses youth migration by attracting tech-industries from cities. “Sustainability is inseparable from energy and inseparable from the process of recycling,” he said.

The forum which drew more than 350 leading minds from architecture, engineering, planning and the construction industry and a total of 1200 attendees, is trying to come up with explored ways of ensuring buildings with higher sustainability and attain greater public support. The experts are actively working on a renovation strategy which not only extends the usable lifespan of the building, but it also delivers multi-layered social, aesthetic, and economic benefits.