PrimaLoft Makes Synthetic Fibre which is Biodegradable

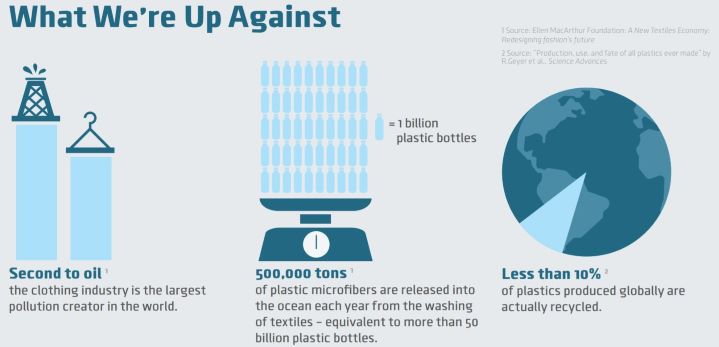

Whenever we picture the problem of plastic pollution in our oceans, we only imagine water filled with plastic water bottles or cups and straws. But what misses our sight is another source of plastic in water -clothing. Every synthetic piece of cloth sheds hundreds of thousands of tiny fibers every time it’s washed. These tiny synthetic fibers make their way through drains and wastewater plants into waterways, where fish ingest them.

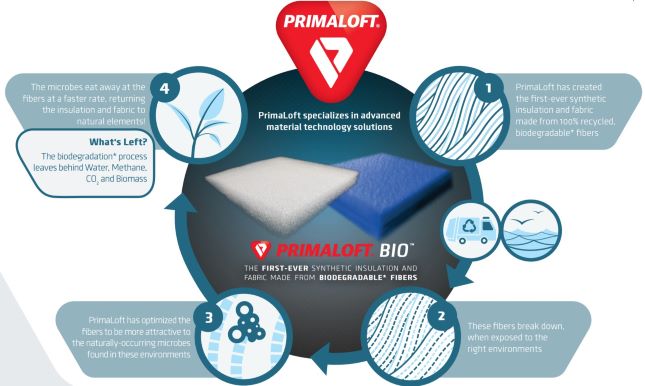

PrimaLoft, the company known for making microfiber insulation that fills jackets made by brands like L.L. Bean, has come up with an alternative to stop this. Its new insulation which is still synthetic–is made from 100% recycled polyester. The twist is if the material ends up in a landfill, unlike other plastic, it will biodegrade relatively quickly. The same holds true if the material ends up in the ocean.

Plastic usually biodegrades at an incredibly slow rate, over hundreds of years. But PrimaLoft’s materials scientists through their two-years research have come up with a way that works differently. For the past one year, they’ve been testing the material in an “accelerated landfill” (where chemical processes help bacteria break down the waste) and a simulation of the ocean to see how quickly it decomposes.

The technology is proprietary, but essentially the company has added a food source for microorganisms present in landfills or water into the polyester.

“The microorganisms are attracted to the material and they feed off it, and as they feed off it, they’re eating the food we’re giving them, but they’re also degrading the polyester at the same time,” says Mike Joyce, President and CEO of PrimaLoft. In landfill tests, the materials reached near complete biodegradation in around a year, and significantly biodegraded in a marine environment.

This is not a complete solution–if the material ends up in the ocean, a fish might still eat it as it waits to biodegrade. But it’s a step above standard plastic. “The material is not going to be sitting there for thousands of years building up on the ocean floor,” he says. (The material only degrades under certain conditions, so a jacket filled with it will be durable for years.)

The company which collaborates with many brands, is working with a handful of brands, including L.L. Bean and plans to bring jackets to market with the new stuffing in 2020. It’s also working with brands to help them use the same technology on other parts of a jacket, like a synthetic lining or shell.

To date PrimaLoft has saved 95 million plastic bottles from landfills and transformed them into premium insulation technologies. By 2020, 90% of Primaloft insulation products will have at least 50% post-consumer recycled content, without compromising performance this includes the introduction of three 100% PCR insulation products, this past year. PrimaLoft expects to continue to push the industry forward with a similar commitment to biodegradable technology across its product portfolio.