Readers might be forgiven for thinking that the only way for energy and emissions heavy sectors like steel making to decarbonise is to use green Hydrogen. There are actually, many other options that could potentially deliver the same benefits faster, and at a lower cost. Today we look at one of the most promising ones, Molten Oxide Electrolysis.

Despite it being one of the supporting pillars for human society, steelmaking has remained more or less the same for the last 2000 years. The archaic method of steel production which relies on blast furnaces that burn carbon intensive fuels like coal means that steelmaking accounts for 10% of global carbon dioxide emissions. For every ton of steel made, two tons of CO2 is released into the atmosphere.

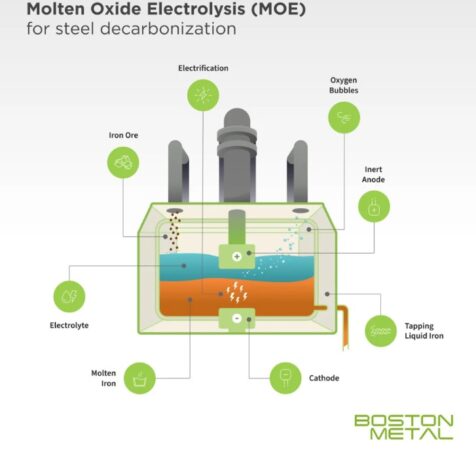

Founded by MIT Professors Emeritus Donald Sadoway, Antoine Allanore and James Yurko, Boston Metal wants to reduce steelmaking’s carbon emissions by completely taking coal out of the equation. Its Molten Oxide Electrolysis (MOE) technology takes place in modular MOE cells, each the size of a school bus. Iron ore rock is fed into the cell, which contains the anode and cathode immersed in a liquid electrolyte. When electricity runs between the anode and cathode, the cell reaches around 1600 degrees Celsius, which produces pure liquid metal that can be tapped. The reaction doesn’t require water, hazardous chemicals or precious metal catalysts. According to experts, 600000 amps could make it so each cell produces 10 tons of metal every day. Steelmakers could deploy as many cells as needed to reach their production targets. When the electricity comes from renewable sources, there are no carbon emissions at all.

MOE has been the recipient of the Fast Company’s World Changing Ideas Award.

Boston Metal recently raised $282 million in a Series C funding round, with investors including the World Banks’ International Finance Corporation, Breakthrough Energy Ventures and Microsoft’s Climate Innovation Fund. The company has also been awarded a $50 million grant by the DOE to construct a factory in West Virginia to onshore production of critical materials including chromium metal, which would lead to the creation of 200 local jobs.

While the technology is slated to reach commercial scale in 2026, a plant in Brazil is already introducing the industry to MOE. This deployment is a massive development towards MOE for green steel in 2026. “This first commercial deployment represents a beacon of progress in advancing sustainable metals production,” said Tadeu Carneiro, CEO of Boston Metal. “As proud as we are today, this is only the beginning. Our high-value metals business will expand rapidly and will support us as we scale our MOE platform to meet the growing global demand for green steel.”

As Kerala strives towards a sustainable future, the Kochi Water Metro Limited (KWML) has revealed…

Kundan Green Energy has acquired Jabalpur MSW Pvt. Ltd., a well-established Waste-to-Energy plant that was…

Agriculture waste to energy conglomerate SAEL is preparing to go public within the next 12…

The Cuttack Municipal Corporation (CMC) and Oil India Limited (OIL) have come together to develop…

India’s Ethanol Blended Petrol (EBP) Programme has emerged as a global benchmark in clean energy…

Refex Renewables & Infrastructure Ltd. has announced that its wholly-owned subsidiary, Refex Green Power, has…