Flexible printed solar cells – a new Innovation by Australian University

New Solar tech to stick around

New Solar tech to stick around

The University of New Castle, from the land down under has come with a new generation of PV solar cells called Organic Photo Voltaic solar cells, that can be printed.

As such, OPV printed solar cells promise to further revolutionise renewables’ by making solar cells sufficiently transparent and flexible that they can be coated on buildings, vehicles and daily consumer items.

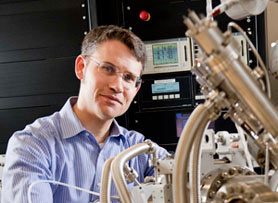

This revolution was promised a decade ago by the US firm Konarka – which never managed to bring the costs down sufficiently, and went bankrupt in 2012. Now the university team led by Professor Paul Dastoor is zeroing in on the costs and looks set to take this forward – by creating a new manufacturing opportunity.

So, what are OPV and how are they different?

The first generation solar photovoltaic revolution has been based on polycrystalline silicon solar cells – which are hard-wired and framed as the original ‘solar cells’.

The cells can be connected together into a ‘panel’ and then the panels can be connected into a solar module, which might have a power output of a few kW. When linked together they can produce ‘solar farms’ operating at MW and even GW-scale.

The technology underpinning such 1G cells is the p-n junction transistor; the panels are manufactured in complex semiconductor processes that call for high temperatures and close manufacturing control.

A 2nd generation of solar PV utilized various ‘thin film’ processes where a thin film of photosensitive material is deposited on glass, such as gallium arsenide (GaAs) or CIGS (cadmium, indium, gallium and selenide).

These 2G solar cells can extract more energy from the sunlight depending on the number of films utilized, to produce hybrid or tandem cells – but they are subject to the same 1G constraint of needing to be deposited on glass, a major cost and flexibility constraint.

Now a range of 3G solar cells are able to overcome this constraint by utilizing non-silicon based photosensitive materials and being printed on polymer sheets (plastic) which makes them light, flexible and low-cost.

The outstanding contenders in this emerging 3G solar cell field are firstly the inorganic cells made from perovskite materials (abundant, cheap, but not yet sufficiently stable for mass utilization) and secondly organic polymer cells, where the photosensitive material is based on carbon molecules, such as those utilizing the fullerene lattice.

These organic solar cells have great promise because the photosensitive material can be formed into an ‘ink’ and deposited at low temperature over a large area of cheap plastic (polymer) through a conventional printing process.

It is these printed, flexible organic solar cells that are being developed by Professor Dastoor and his team at the University of Newcastle, in the Priority Research Centre for Organic Electronics and in the Newcastle Institute for Energy and Resources (NIER).

A key feature of the OPV cells is that they have no toxic ingredients, as compared with some of the alternative inorganic solar cells being developed.

The difference between what is being done at Newcastle and what was accomplished by Konarka a decade ago is the new focus on costs, to keep the cost of the various fabricated photosensitive materials as low as possible.

This will partly be a function of scale of production, but partly also the judicious choice of materials involved. The whole process does not have to utilise semiconductor fabrication techniques that has made the process of producing 1G and 2G solar cells so complex.

The Newcastle team at this stage is concerned to create a workable prototype of a functioning solar PV array. This has been accomplished, in a world-first 200 square-meter array erected on the roof of an industrial complex near Newcastle, by the bulk liquids and containers firm CHEP.

How do 3G OPV solar cells perform?

First, the costs. Professor Dastoor and his team believe that they can print these OPV solar cells for less than $10 per square meter – because the process is not complex, uses abundant and low-cost materials, and can be accomplished with standard printing technology. Scaling up to commercial quantities, of the square-kilometre range, the costs would be less than $10 million per square kilometre.

According to the university, they want to scale the CHEP prototype up through the following calculation:

Working from the insolation received at the earth’s surface of 1000 W/m2, and assuming an unrealistically low level of conversion efficiency of 1% would mean that the OPVs would produce power at a rate of 10 W/m2. Scaling this up (and assuming effectively no limit to the availability of polymer substrate for the OPVs) would mean that a system could produce 10 MW from a sheet 1 km2 in area.

Professor Dastoor considers the ‘sweet spot’ for this technology to be around 20 to 30 MW per km2, where (according to his group’s calculations) the OPV would deliver electrical energy at a levelized cost of 20 cents per kWh. That’s Rs 10 per kWH.

So efficiency in sunlight conversion would only need to be improved 2 to 3 times to achieve such a ‘sweet spot’ – something which is actively being investigated by the Newcastle group.

Professor Dastoor calculates that if a large area of OPV could produce power at the rate of 50 to 60 MW/km2 (raising the conversion efficiency 5 to 6 times) then power could be produced at a levelized cost even lower, at around 10 to 11 cents per kWh (Approx Rs 5.50) – highly competitive with present costs of power produced by burning fossil fuels.

So the key cost and power parameters are as follows. A printed OPV solar cell would cost less than $10 per m2, which would scale to $10 million per km2 – enough to cover several blocks of city buildings.

Power would be generated at 10 W/m2, or scaled up at 10 MW/km2. So a city block of several buildings could be producing its own power at 10 MW at an installation cost of less than $10 million.

A key target for research at UoN would be to validate these calculations with actual observations of power and energy generated by the experimental array installed at CHEP.