Indian Scientists Develop An Improved Catalyst for Faster Conversion of Biomass to Biofuel

Scientists at the National Chemical Laboratory (NCL), Pune, have developed a faster, environment-friendly method for conversion of industrial biomass into biodiesel. In the race to find greener alternatives for our daily fuel consumption, of petrol and Diesel, which has skyrocketed to 4.5 Billion barrels per day currently, the government has been trying to diversify its basket of fuels with alternate sources.

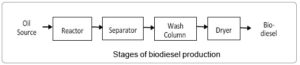

Conversion of biomass into biodiesel involves a range of chemical processes. An organic compound called furfural is produced from agricultural waste biomass like bagasse, cotton seed hulls, sawdust, oat hulls, rice hulls, wheat husk and bran. Typically furfural is first chemically changed into furfuryl alcohol. It is processed further to produce alkyl levulinates, such as ethyl levulinate.

The process, however, involves multiple steps and takes a relatively long time. The NCL team has developed a new version of zeolite catalyst – HPW/Meso-HZ-5 – which can speed up the process of conversion. The catalyst exhibits good performance with 100% furfural alcohol conversion along with 97% ethyl levulinate biodiesel yield and 3% ethoxy methyl furan yield. Ethoxy methyl furan is used as a food additive. The catalyst showed superior activity compared to the parent H-ZSM-5 and Meso-HZ-5 used separately.

“Due to higher number of active sites and larger pore size, the travel distance is reduced, improving accessibility of active sites. Low molar ratio of reactants would do away with the separation cost associated with unreacted ethanol, operational cost and reactor size, making the process economically viable and industrially safe,” researchers said.

Globally, researchers are seeking to explore biomass as a sustainable alternative feedstock. Ethyl levulinate is one of the top ten biomass-derived ‘building blocks’ recognized for use in bio-refineries. It is a renewable oxygenate additive and can be added to diesel.

Importance of Biomass Energy in India

Energy consumption is increasing at 6.5 percent per annum, while reserves of petroleum are decreasing day by day. India’s share of crude oil production is about 1 percent of global crude oil production, whereas consumption amounts to 3.1 percent of global consumption

- India produces about 450-500 million tonnes of biomass per year. Biomass provides 32% of all the primary sector’s energy use in the country.

- EAI estimates that the potential in the short term for power from biomass in India varies from about 18,000 MW, when the scope of biomass is as traditionally defined, to a high of about 50,000 MW if one were to expand the scope of the definition of biomass.

- The current share of biofuels in total fuel consumption is extremely low and is confined mainly to 5% blending of ethanol in gasoline, which the government has made mandatory in 10 states.

- Currently, biodiesel is not sold on the Indian fuel market, but the government has set a target to meet 20% of the country’s diesel requirements by 2020 using biodiesel.

- Plants like Jatropha curcas, Neem, Mahua, and other wild plants are identified as the potential sources for biodiesel production in India.

- There are about 63 million hectares wasteland in the country, out of which about 40 million ha area can be developed by undertaking plantations of Jatropha. India uses several incentive schemes to induce villagers to rehabilitate wastelands through the cultivation of Jatropha.

India is among the leading producers of rice, pulses, wheat, and the world’s second largest producer of sugarcane. A large amount of agricultural waste is produced. Converting this non-food waste into furfural and upgrading it further to biodiesel could give additional income to farmers and also generate employment.