India’s biogas sector to offer opportunities for the next 5-10 years: Jan and Anting, Weber Entec

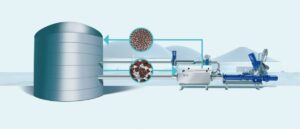

With India's biogas sector gathering pace, German conglomerate Weber Entec—known for its cutting-edge ultrasonic technology—made its presence felt at the REI Expo in Greater Noida, India. Specializing in the turnkey design and construction of ultrasound-based environmental applications, Weber Entec focuses on the ultrasonic treatment of biogenic materials, a process known as disintegration. In an insightful conversation with Subhash Chandra Yadav from IAmRenew, Jan Talkenberger, Head of Sales, and Anting Grams, Technical Director & Head of R&D, discuss the ground-breaking disintegration technology aimed at boosting biogas plant efficiency, along with the company’s plans for growth in India. Read the full conversation:

How do you find the Indian CBG market on this visit? What’s the general sentiment?

Jan Talkenberger: I was excited to see the pace you people have developed biogas business here in India. From what I knew one year ago and now, a lot of things developed very quickly. We had some good discussions (with the industry people). India with its potential could play a big role as one of the biggest bioenergy producers for sure. It’s still a long way to go. The pace & potential of Indian biogas market surely makes it one of the most important markets in the world.

How is Weber’s business performing in India? What does India represent for you?

Jan Talkenberger: We are close to having two installations which we have developed in the last two months. We are happy to be here and we would accelerate. If India develops into the biggest biogas market, it will have potential for us. We would help the biogas industry through substrate treatment because it’s the difficult substrate that you use here. It’s good to us being the part of a growing economy and it’s encouraging.

Anting, you’ve been here for a while now. What changes have you noticed in the Indian biogas industry over the past year?

Anting Grams: It has been great as we have quickly learnt about potential customers in past one year. It’s quite amazing how the market is going forward to successfully run biogas projects. We have much more detailed discussions now because the technical knowledge (among the stakeholders) is much higher here. Now the developers know how biogas works; what is necessary. They know how important the smaller steps are like feeding, steering or disintegration system.

How has Weber adapted to meet the unique demands of the Indian market?

Anting Grams: Our technology is specific one which helps biogas plants to reduce viscosity and producers can use Napier grass & paddy straw to operate their plants. So, as more projects are realised, there is more potential for us. The first plants are coming up and we are having deeper discussions with regards to reducing viscosity. The market is on a step where they think about ways to solve the issue of viscosity. The Napier is also now growing in the right direction especially for us.

How does your ultrasound technology enhance paddy digestion in biogas projects?

Anting Grams: We treat the feedstock digesting in digesters. Out ultrasound machine helps destroy the fibre at cellular level. After this disintegration, the fibre can no longer fix with water. We release the water and the viscosity goes down. What we have learnt here in past few days is that there are huge problems in the operations of the newly built biogas plants. They don’t get the gas yield. Weber Entec can reduce viscosity and increase the gas output.

What is your plan moving forward for the Indian market?

Jan Talkenberger: We will be allocating few more resources in the future because the number of projects coming up is very big. We will certainly work with our local partners who are very well trained. They can give service & advice locally. We want to see more projects where we can evolve. What I really like is the zeal of the people here in learning and understanding things quickly.

In which other countries, similar to India’s situation, do you have installations?

Jan Talkenberger: We have got installations in Thailand, Malaysia, Singapore and Hong-Kong, and also in China, Korea and Japan. If we work with skilled people, everything gets easier.

Would you say that Indian biogas projects are efficient enough?

Jan Talkenberger: A few among what we have seen are well managed and running properly. There are still a lot that can be improved. The biogas in this country is growing fast, so everything will be developed. What is important is to build projects, properly set-up digesters etc. and then improve thereafter. There will be enough opportunities for us in the coming 5-10 years.