Even as the demand for green hydrogen with a carbon negative approach and at lower costs gathers steam, US based Cleantech start up, Mote has announced setting up one of the world’s first carbon removal project that will enable conversion of biomass to hydrogen. Mote said that the $100M carbon capture plant spread over five acres of land will root out carbon dioxide from wood waste to produce hydrogen fuel.

As per various estimates, more than 500 million metric tons of wood and agricultural waste are generated every year in the US. The carbon present in the waste returns to the atmosphere as the waste is either disposed of via natural decay, landfills, or open-air burn.

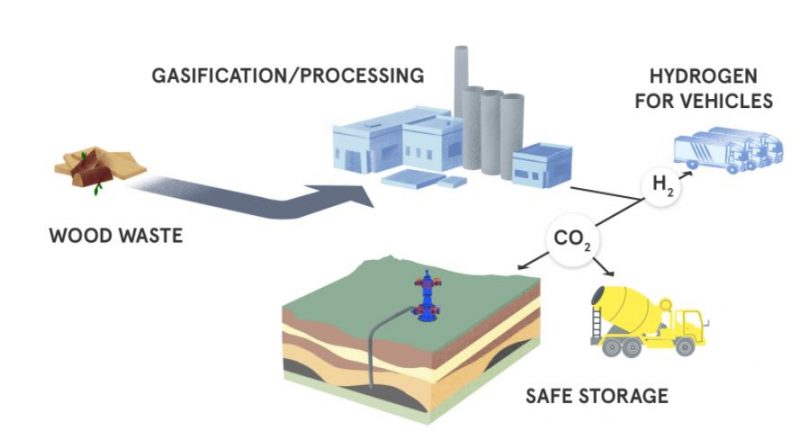

The planned facility will be the first that will convert wood waste into hydrogen fuel while capturing, utilizing, and sequestering carbon dioxide (CO2) emissions resulting from its process. The company expects to produce approximately seven million kilograms of carbon-negative hydrogen (7000 tonnes) and remove 150,000 metric tons of CO2 from the air annually. Production is expected to start by 2024.

Biomass, a renewable organic resource, includes agriculture crop residues (such as corn stover or wheat straw), forest residues, special crops grown specifically for energy use (such as switchgrass or willow trees), organic municipal solid waste, and animal wastes. So far, biomass has been used to generate power or even bio-gas , but the move to green hydrogen is a first. Keep in mind that Biomass has a somewhat contentious status in the eyes of many, where it uses wood, unlike agri residues.

The potential of conversion of wood waste into hydrogen fuel is a technology that is being explored for more than a decade. It is now that the biomass gasification conversion has become a prominent technology to produce hydrogen from biomass. The concentration of hydrogen in the gas generated from gasification depends on many factors like moisture content, type and composition of biomass, operating conditions, and configuration of the biomass gasifier. The technology has not matured till now, and involves heat, steam, and oxygen to convert biomass to hydrogen and other products, without combustion.

As growing biomass removes carbon dioxide from the atmosphere, the net carbon emissions of this method can be low, especially if coupled with carbon capture, utilization, and storage in the long term. Mote will utilize wood waste from farms, forestry, and other resources where it would otherwise be burned in open-air, left to decompose, or sent to a landfill. Through gasification and subsequent treatment processes, the remaining carbon dioxide is extracted and permanently placed deep underground for ecologically safe storage.

To build the plant, Mote will team up with Irving, Texas-based engineering and construction firm Fluor Corp. and SunGas Renewables, a subsidiary of Des Plaines, Ill.-based GTI International Inc. that makes gasification systems.

After getting the requisite approvals, the construction could begin towards the end of 2022 with operations scheduled sometime in 2024.

Some of the carbon dioxide would be stored underground, where it could generate credits that industrial companies could buy to meet carbon emission reduction mandates. The company is also looking to sell some of the carbon dioxide to concrete producers, who would inject it into their concrete.

The company also intends to sell one of the biproducts of this carbon extraction process — hydrogen gas — to hydrogen fuel station operators.

A recent report to Congress published by the White House Council on Environmental Quality (CEQ) in June 2021 said that for US, to reach the ambitious domestic climate goal of net-zero emissions economy-wide by 2050, it will have to capture, transport, and permanently sequester significant quantities of carbon dioxide (CO2).

The report added that there is growing scientific consensus that carbon capture, utilization, and sequestration (CCUS) and carbon dioxide removal (CDR) will likely play an important role in decarbonization efforts globally; action in the United States can drive down technology costs, accelerating CCUS deployment around the world.

US already has a head start on CCUS and CDR in part because the country’s oil and gas industry has long used CO2 to boost production. Drillers can inject CO2 underground to free oil trapped in geologic formations – a process known as enhanced oil recovery. The 5,200 miles of dedicated CO2 pipelines that crisscross the US delivered 52 million tonnes of CO2 for EOR in 2019.

But current and planned carbon capture and removal activities extend well beyond these oil industry roots. “The United States has more CCUS activities planned and proposed than any other country”, with 45 CCUS facilities in operation or in development, according to CEQ.

The US administration wants carbon capture and removal technologies to be capable of operating at the “gigatonne” scale by 2050. One gigatonne of sequestered CO2 would be equivalent to the emissions from all 250 million US light-duty vehicles driven for one year, according to the US Department of Energy (DOE).

Mote CEO, Mac Kennedy said, “As the world’s first carbon removal project converting biomass to hydrogen, we are addressing the ever-growing demand for renewable hydrogen with a carbon-negative approach,” says co-founder and CEO Mac Kennedy. “Our pioneered technology directly supports California in its carbon-neutrality goals by removing carbon dioxide from the atmosphere with our wood waste conversion process.

India is undergoing a significant influx of urban migration and a reclassification of rural areas,…

India’s quest toward green hydrogen economy received a significant boost with a strategic MoU between…

A new report by S&P Global has revealed that India’s growing biofuels industry is emerging…

In a significant breakthrough for India’s renewable energy and dairy sectors, dairy major Amul has…

Renewable energy conglomerate Anaergia Inc, through its subsidiary, Anaergia S.r.l., entered into a contract with…

Reliance Industries Ltd (RIL) Chairman Mukesh Ambani has announced a massive ₹75,000 crore investment in…