Our Ultrasonic Technology breaks substrates at microscopic levels; increases biogas production by upto 25%: Christian Eichhorst, Managing Director, Weber Entec GmbH & Co. KG

1. Weber Entec is among top innovators in the bioenergy sector in Europe. How has Weber helped the European biogas sector?

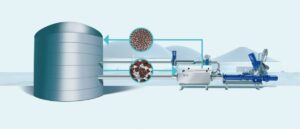

Christian Eichhorst: We help the European biogas sector in many ways. First of all, our technology is increasing the biogas yield. So wherever our technology is applied, the plant gets upto 25% more biogas depending on the biogas plant. On the average we perform 13% more biogas but that’s not all. Especially in Europe or in Germany where the biogas market has seen the biggest growth in the past few years, we are using energy crops like corn to produce biogas. As you know corn is not suitable – has never been – as its feed and corn has to be substituted by other substrates like agricultural waste, manure etc. These are more difficult to digest. So the biogas plants need whatever kind of technology to really break it up at microscopic level. And that’s the technology we are providing to perform this function. Any biogas project anywhere in the world that wants to go away from energy crops like corn and use more difficult substrates, needs technology like ours.

2. What makes Weber Entec enter the Indian biogas sector?

Christian Eichhorst: Our technology will increase the yield of Indian biogas plants whatever substrates the plants use. Another thing that I am really looking into is that India is going to use more & more Napier Grass. The Napier Grass will lead to thickening of the digester. That is a known problem like with the grass in Europe. Weber Entec ultrasonic technology is helping significantly to reduce viscosity to make those kinds of substrates really applicable in biogas plants. Without our technology it would be difficult for these biogas plants.

3. The Indian biogas industry is expected to use a wide range of raw material feed including paddy straw, cotton stalk, cane, Napier grass etc. and projects will be located in extremely diverse climatic zones. How adaptive and effective will Weber Entec ultrasonic technology be in such a scenario?

Christian Eichhorst: It will be beneficial in India as well because if you use rice straw or any straw, you have to mash it in the feeding line. Once you put it in the digester and there comes the role of our technology. We are breaking up the substrate really at the microscopic level or cellular level that increases the surface of the substrate. It gives faster & better digestible nutrition to the bacteria. This accelerates the enzymatic activities and bacteriological activities. Therefore, it accelerates digestion time and leads to more biogas. So you increase your biogas production.

4. With regards to the increase in biogas yield claim, what is your European experience?

Christian Eichhorst: Currently, we have more than 200 machines installed in Europe. On average we are performing 13-14% more biogas. Some plants give 20% and some only 10% more. It depends on the substrates’ use in the biogas plants.

5. Pricing is a crucial factor in India. How price competitive is Weber Entec?

Christian Eichhorst: We are competitive in any case. The business case cannot be very much different in India than it is in Germany or the UK. Typical return on investment (RoI) of our technology is that the bigger the biogas plant is, the faster the return on investment. We have amortisation time 2-3 years. That makes our ultrasonic technology price competitive in any case because the business case is very positive.

6. How exactly Weber Entec helps is reducing operational costs of biogas plants? Can you elaborate on this?

Christian Eichhorst: First of all we are reducing viscosity. So we make the biomass really much more liquid which is easier to pump and easier to steer. Where it really helps are two things. First of all, we significantly reduce the energy demand for pumping and steering in the biogas plant. We also reduce the steering time. Also, by having substrate more liquid, we reduce the maintenance impact because it’s much easier for steering staff to move around with a liquid material vis-à-vis stiff material. Reduced power consumption means reduced operational costs.

7. What are other services you look to offer to the biogas industry in India?

Christian Eichhorst: We are very much focusing on the ultrasonic technology only which is our specific field of operation. What we will bring – and we always bring on the table – is our vast experience in the biogas market. We have analyzed more than 1000 biogas plants in the last 15 years. On top we have 200 installations worldwide proving that we have a vast range of experience. This kind of experience will come free of cost as a gift with our technology for our customers.

8. The Indian Government has recently announced a new policy of mandatory biogas blending with natural gas in a phased manner. How do you think this will play out for players like Weber Entec?

Christian Eichhorst: I find it a very reasonable policy. This will obviously increase the demand for biogas plants and you will need to build more plants. I have been to a trade show recently in India where I learnt about this initiative of the Indian government. I was very much impressed. I think it will definitely be a booster and create a demand for European companies to support India in this.

9. What problems or challenges do you think India can face in its biogas journey?

Christian Eichhorst: The challenge for India may come up in price for biogas. The production cost of biogas is higher than that of natural gas. But intelligent government policy can help there. What we have learnt in Europe is that investors or the operators of biogas need consistency in policies. Once rules are set-up for the industry, you need to ensure that the policies are not revoked after a few years to threaten their investments. India is big and you have a lot of waste. Any kind of organic waste is a treasure in the future because anything that is organic produces biogas. The challenge is most likely to be on the logistic side – collection and preparation for biogas plants. Overall, I see an interesting and feasible market in India.

10. India has a plethora of landfills and huge amounts of legacy waste available for biogas production. How does Weber Entec ultrasonic technology perform there?

Christian Eichhorst: We have several plants which are using food waste, kitchen waste or other household waste. We are like the tuning chip of a car. We make a running car even faster. With increase in the surface, we accelerate the biology. Food waste, for example, is very easy to digest. We have a plant where we increased the biogas production by 17% as much. Often your retention time in the digester is limited because you have lots of waste and no endless volume. That leads to the necessity to accelerate biology. That is exactly what the ultrasonic technology of Weber Entec is doing. Our technology virtually increases the digester volume.

11. Do you have any India-specific plan that you want to share?

Christian Eichhorst: We started a year ago to look into the Indian market. We are active in other fields like chemical industry & pharma where we can foray in India. But at this point of time, we are very much focusing on biogas and wastewater.

12. How will 2024 be for the Indian biogas industry and Weber Entec?

Christian Eichhorst: I saw the dynamics of the Indian biogas industry at the trade show (REI Expo) in Delhi last year. It was impressive. There is a lot going on and I’m positive that India will have a significant growth in the biogas market. We also have the hope and expectation that we will set up one or two pilot plants in India. We will show to the market and biogas community what our technology can deliver.