Macawber Beekay to build 3 waste-to-green coal projects for NTPC

The largest project, with a capacity of 900 tonnes per day (TPD), will be established in Noida, while Bhopal and Hubbali will have capacities of 500 and 400 TPD, respectively.

Noida headquartered Macawber Beekay Private Ltd has announced that it has secured three Green Coal projects from state-owned NTPC. The three Green Coal projects will be executed in Noida (Uttar Pradesh), Bhopal (Madhya Pradesh), and Hubbali (Karnataka). Macawber Beekay is a company that specializes in the waste-to-energy segment.

Macawber Beekay said in its official statement that the largest project, with a capacity of 900 tonnes per day (TPD), will be established in Noida, while Bhopal and Hubbali will have capacities of 500 and 400 TPD, respectively.

Recently, Macawber Beekay commissioned a Green Coal project in Varanasi. Including this project, all four projects will collectively handle 2400 tonnes of municipal solid waste (MSW) per day by August 2025. As per the details, NTPC is expected to receive over 800 tonnes of Green Coal per day from these projects.

Macawber Beekay claims to be leading complete turnkey solutions provider to power industry for segments like ash handling, slurry disposal system, coal handling systems, pneumatic coal mill rejects handling systems, ship/barge fly ash loading system and mine void filling system.

Gautam Gupta, Joint Managing Director of Macawber Beekay, stated, “In terms of technological enhancements, we are upgrading the existing technology with innovations derived from our experience in Varanasi by continuous research and development.”

“These refinements will not only bolster efficiency but also ensure the seamless integration of these advancements into our operations in Varanasi and the upcoming projects,” said Gupta.

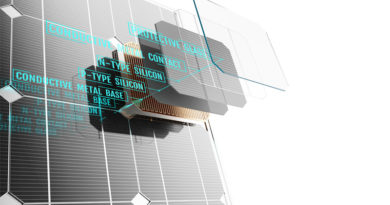

Green Coal is charcoal produced from MSW through a thermal treatment process known as torrefaction, which occurs in an oxygen-deficient environment. The process initiates combustion using biomass pellets made from agro-waste and generates volatile gases that heat the dryer and reactor during the conversion of MSW into charcoal. Macawber Beekay held that this method minimizes emissions and makes the system self-sustainable.