Dutch Firm Lithium Werks goes beyond cars and electronics for storage solutions

Powering your trucks

Powering your trucks

While environmentally conscious consumers and investors focus on automakers such as Tesla, Nissan, and BMW, Heavy industries from ships and trains to mining and construction are also poised to shift away from fossil fuels. Keeping their businesses in mind, Kees Koolen, chairman of Lithium Werks BV, the Dutch company has a clear plan to serve them. “We want to work on the electrification of everything that isn’t cars and consumer electronics,” he says. “Those markets are already saturated, and we see a big opportunity beyond them.”

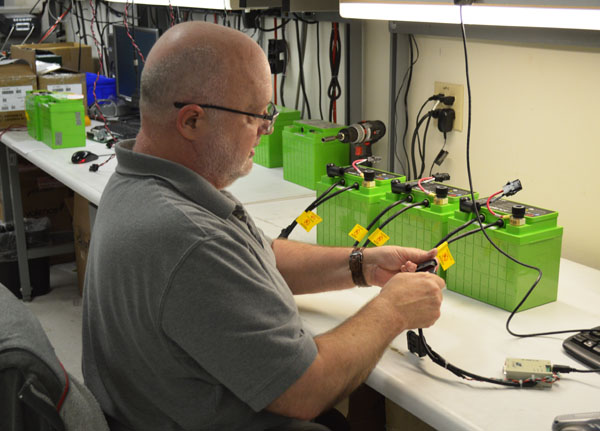

Koolen, an early investor in Uber Technologies Inc. and Booking.com, besides being an avid rally racer, is betting he can make a fortune producing batteries for everything from forklifts to giant dozers. Power packs for bulky machines can have more heft than those for cars or devices such as cellphones or tablets, which put a premium on being small and light. Another potential market is massive batteries to help plug gaps in output from wind and solar plants—a job currently done by conventional power plants. Lithium Werks has bought three start ups with specialisations ranging from chemical cells to systems that manage a battery’s output, and Koolen plans to set up production plants around the world that combine the expertise of his stable of companies. This year he opened his first factory, near Shanghai, and he’s planning two more in 2019—one in Mexico and a second in China.

Making new product development at its core the Energy management company has also announced that it will build a 42-acre, clean energy research and development (R&D) campus at Twente Airport. “In order to achieve a real transition, from fossil fuels to renewables, energy has to be available in the right place and at the right time,” said Koolen. “Over the next five years, we will recruit some 2,000 people to develop clean energy technologies at the campus.”

Lithium Werks, which has supplied 200 million battery cells to more than 1,000 customers in 50 countries, currently produces lithium iron phosphate batteries, or LFP. For the next generations of batteries, Lithium Werks is collaborating with the University of Twente, a pioneer in research in the field of new materials, artificial intelligence and control electronics.

“Renewable energy sources, such as wind and sun, often produce the most energy at times when the demand is low. This mismatch between supply and demand means it is still necessary to have conventional coal or gas power stations. With smart energy storage and transport solutions, the energy will be available at the right time and place. This will require both sufficient battery capacity – we need to produce many more batteries – and artificial intelligence software,” said Koolen.

Growing demand for electric vehicles is a key driver of the rising demand for batteries. By 2025, Koolen plans to have 10 plants, at a total cost of $2 billion, each with output of 1 gigawatt hour a year, enough for 20,000 electric cars. Market expert, Bloomberg, predicts that demand for batteries will climb to almost 1,800 GWh by 2030, from about 120 GWh this year. While 85 percent of that will go into cars, there’s plenty of money to be made in the industry’s niches. But the game is not that easy for Lithium Werks, there is intense competition in this segment too. Switzerland’s Leclanché, Germany’s Bosch, and Saft Groupe, taken over by French oil major Total, are all focusing on stationary storage. Whereas, manufacturing heavyweights such as BYD, LG Chem, and Samsung SDI produce millions of battery cells that are easily adaptable for industrial use. Also, Tesla has invested $5 billion in its Gigafactory in Nevada, which can produce 20 GWh of batteries a year. Companies worldwide have spent almost $17 billion on battery production facilities since 2008, largely in China, and by 2022 total investment can easily approach $60 billion mark.