Transforming Wastewater into Clean Energy, Chile Sets an Example India will do well to follow

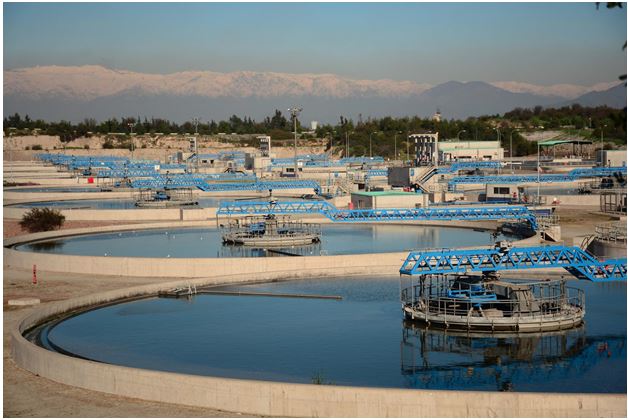

Aguas Andinas, Chile’s largest water utility company together with its main shareholder SUEZ, is transforming the capital’s three wastewater treatment plants into “biofactories” that convert wastewater and sewer sludge, a wastewater treatment by-product, into clean energy.

.@aguas_andinas & @suez are treating 100% of Santiago’s wastewater -which has resulted in the recovery of the Mapocho river- and turning sewer sludge into clean energy. https://t.co/9afINSqnin Congratulations to the @Momentum_UNFCCC award! #ClimateAction #LighthouseActivities pic.twitter.com/w8c390vOuj

— UN Climate Change (@UNFCCC) October 5, 2018

Winner of the 2018 United Nations ‘Momentum for Change’ climate action award, the project was launched in 2017, and aims to pioneer innovative circular wastewater treatment solutions in Santiago and to push the boundaries of human health and environment preservation standards in the sector. The company expects that all three treatment plants will be zero waste, energy self-sufficient, and carbon neutral by 2022.

In 2005, Santiago was only treating 3.6% of its wastewater. The remaining, untreated water and resulting sewer sludge flowed freely into the Mapocho River, a 110-km river that divides Santiago in two, an important source of irrigation and potable water for the region. Enteric diseases used to be common because the region’s agricultural areas were irrigated with the polluted river water.

To fight this problem, Aguas Andinas decided to use the circular economy model to eliminate waste, fossil energy and pollution from its wastewater treatment processes. The circular economy model aims to keep resources in use for as long as possible. Today, Santiago has three wastewater treatment plants that combined consume 134 GWh of energy and process 300,000 tonnes annually of “sewer sludge”.

Wastewater loaded with organic matter and other solids, like sand are directed towards the three biofactories. After the water is treated, cleaned and recycled sand is used for city construction projects or for gardening and agricultural purposes. The disinfected water is then discharged into the natural environment and can serve as a clean source of irrigation.

Among the waste produced in biofactories, sewer sludge is recovered through the extraction of biogas that is converted to electricity through cogeneration. This energy is mainly used for self-supply, but can also be fed back into the grid if there is a surplus. Additionally, 137,000 tonnes of biosolids sludge is being used as fertilizer for agriculture. Energy recovery from sewer sludge leads to the production of 49 GWh of electricity, 177 GWh of natural gas, and 84 GWh of thermal energy in Santiago.

The company achieved its goal of treating 100% of Santiago’s wastewater, which has resulted in the recovery of the Mapocho River and the surrounding ecosystems. Once classified as a dead zone, life has returned to the river.

Climate action is a key part of implementing the #ParisAgreement. These 15 #climateaction projects are helping to lead the way. https://t.co/OL5bO3E0g5 @Momentum_UNFCCC #ClimateWeekNYC @PEspinosaC pic.twitter.com/ZqSu9jh4TO

— Momentum for Change (@Momentum_UNFCCC) September 27, 2018

Due to population growth, accelerated urbanization, and economic development, the quantity of wastewater generated and its overall pollution load are increasing globally. The creation of biofactories could have significant scalable benefits both in terms of greenhouse gas mitigation and adaptation to the effects of climate change on water resources.

In the Indian context, practically every Indian city with a population over a million could benefit from such an approach. Not only is groundwater over exploited in most cases, waste water recycling remains at pitifully low levels across the country. With predictions of a wider crisis as early as 2030 of leaving half the country’s population without access to clean drinking water, and an even worse crisis on hand for some of India’s biggest metros like Delhi, Hyderabad, Bengaluru running out of ground water by 2020, according to a NITI AAYOG report. It is high time policy makers started doing something real on ground to prepare these cities better for a water scarce future.