Utah Engineers Develop Fast Method To Convert Algae To Biocrude

Swomitra Mohanty, Assistant Professor of Chemical Engineering, University of Utah

Swomitra Mohanty, Assistant Professor of Chemical Engineering, University of Utah

Biofuel experts have long sought an economically-viable way to turn algae into biocrude oil to power vehicles, ships and even jets. This is important not only because of the needto make the process ‘greener’, but also because there are clear limitations to creating biofuel out of say, corn, as the US set out to do so enthusiastically. Researchers at the University of Utah believe they may have found one such way.

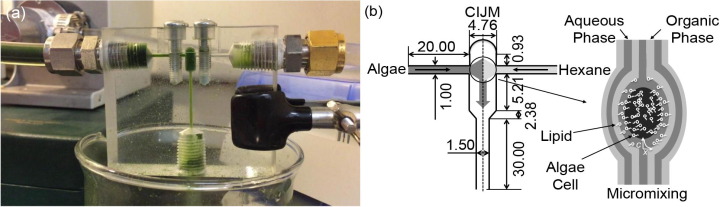

The University has released a study called, “Algal lipid extraction using confined impinging jet mixers” in which chemical engineers have developed a rapid method to deliver cost-effective algal biocrude in large quantities using a specially-designed jet mixer.

This new kind of jet mixer extracts the lipids in seconds with much less energy than the older extraction method, claims the release.

Currently, in order to extract the oil-rich lipids from the algae, scientists have to remove the water from the algae first, leaving either a slurry or dry powder of the biomass. This is the most energy-intensive part of the process. The residue is then mixed with a solvent where the lipids are separated from the biomass. What’s left is a precursor to the biocrude, eventually used to produce algae-based biofuel. That fuel is then mixed with diesel fuel to power long-haul trucks, tractors and other large diesel-powered machinery. But because it requires so much energy to extract the water from the plants at the beginning of the process, turning algae into biofuel has thus far not been a practical, efficient or economical process. Under current methods, it takes more energy to turn algae into biocrude than the amount of energy you receive from the process. A bummer, in other words.

“The key piece here is trying to get energy parity. We’re not there yet, but this is a really important step toward accomplishing it,” said Leonard Pease, co-author of the paper. “We have removed a significant development barrier to make algal biofuel production more efficient and smarter. Our method puts us much closer to creating biofuels energy parity than we were before.”

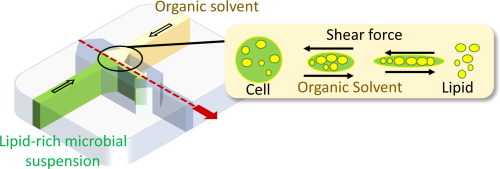

The team has created a new mixing extractor, a reactor that shoots jets of the solvent at jets of algae, creating a localized turbulence in which the lipids “jump” a short distance into the stream of solvent. The solvent then is taken out and can be recycled to be used again in the process.

“Our designs ensure you don’t have to expend all that energy in drying the algae and are much more rapid than competing technologies,” notes Swomitra Mohanty, a co-author on the paper.

This technology could also be applied beyond algae and include a variety of microorganisms such as bacteria, fungi, or any microbial-derived oil, says Mohanty.

Although the energy industry has been investigating algae since the 1970s as a source of biodiesel to supplement petroleum-based fuels, the technical difficulties in developing algal biofuel has remained. Among the energy giants ExxonMobil and Synthetic Genomics have been working to boost the oil concentration in algae — another important step in biofuel production.

Algae can in principle produce seven times more energy per acre than corn-based or sugarcane based ethanol , the main source of biofuel today. Other advantages include the ability of algae to grow in salt water and thrive in harsh environmental conditions — limiting the pressure on farmland and fresh water supplies. Algal oil could be processed in conventional refineries, producing fuel that can substitute directly for petrol or diesel.